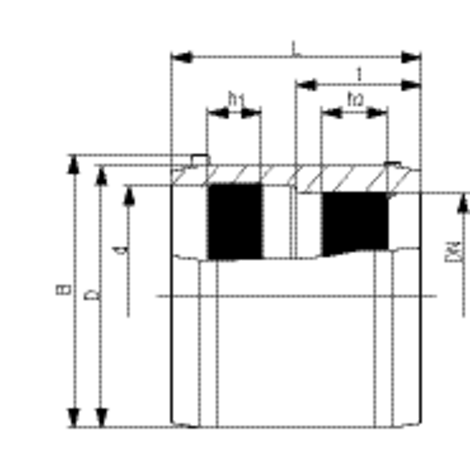

| Indeks | d | Opak. | Paleta | D | t | h1 | h2 | B | Masa kg/szt. |

|---|---|---|---|---|---|---|---|---|---|

| 615571 | 160 | 12 | 96 | 190 | 90 | 38 | 42 | 199 | 1,550 |

| 615576 | 315 | 1 | 18 | 355 | 150 | 78 | 83 | 355 | 7,950 |